For the traditional jewelry industry, jewelry manufacturers are a very important link in the mid- to downstream industry chain, production-distribution-retail-consumers. Although consumers bear most of the intermediate transition costs, they do not have to worry about quality risks. The risk part All are borne by dealers and retailers, and they also have value-added services such as warranty and returns.

For jewelry practitioners, whether they want to start a jewelry business or expand their business, finding a reputable and powerful manufacturer is a top priority. This guide will answer all your questions about how to find a jewelry manufacturer.

How to find a jewelry manufacturer?

Determine your jewelry manufacturing needs

Before you start looking for a jewelry manufacturer, you need to know what you want. Because not all manufacturers can meet the production and manufacturing needs of all categories and styles, more are specialized in a certain material and category. Be prepared with the type of jewelry you plan to produce, the materials your target audience will prefer, and an estimated production scale. These preliminary preparations will guide you to better search for jewelry manufacturers, and communication and subsequent signing will be smoother.

Google to find jewelry manufacturers

Keyword search: Enter “jewelry manufacturer“, “custom jewelry manufacturer” or “wholesale jewelry supplier” to search. If you want to find a specific region, you can add the region name as a suffix to search.

Google Business Listings: Most feature businesses have a registered presence on Google with very detailed reviews, ratings, and contact information. This effectively helps people understand the scope of services and credibility immediately.

Google Ads: Some manufacturers use Google Ads to promote their business. These ads usually appear at the top of search results.

Online catalog to find jewelry manufacturers

Choose the right directory: Choose an online directory that specializes in B2B listings, targeting the jewelry industry. Examples include Alibaba, Made in China, and Compass, which are currently the largest B2B online catalog sites.

Utilize search filters: The catalog has search filters to search for manufacturers that match you based on location, jewelry type (e.g., fine jewelry, fashion jewelry), manufacturing capabilities (e.g., cast, handmade).

Check for certifications and compliance: Check for qualified manufacturers for the qualifications required for the category you operate in.

View product catalogs: Jewelry manufacturers will display their product portfolios and product catalogs to check whether the jewelry products they manufacture match your business style and whether they have future sales potential.

How to assess quality and reliability

Assessing the caliber and dependability of a possible jewelry producer is essential. Seek out producers who have an excellent track record, a portfolio of high-quality products, and favorable consumer feedback. Visit a production site if you can to gain personal knowledge of its procedures , workforce, and quality assurance systems. This visit sheds light on their meticulousness and operational effectiveness.

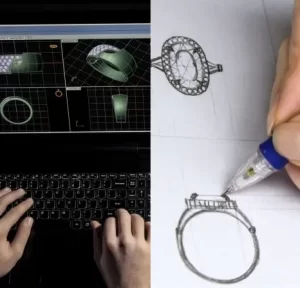

Different Types of Jewelry Manufacturing Techniques

The process of making jewelry involves a range of approaches, from sophisticated CAD/CAM processes to conventional handcrafting. It will be easier for you to select a manufacturer with the right experience if you are aware of these technologies. For instance, stamping works well for pieces with great strength, yet casting works well for intricate designs. The level of proficiency a manufacturer has with a particular technology can have a big effect on the product’s overall quality.

Estimated costs: materials and labor

Price is a major consideration when selecting a jewelry manufacturer. It’s critical to comprehend all associated expenditures, including those for labor, supplies, and any other levies. To find the greatest deal, ask many manufacturers for specific quotations so you can compare and bargain. Unusually low quotes should raise red flags since they can mean that moral or quality standards have been compromised.

Ensure quality and consistency of production

Making jewelry requires careful attention to quality assurance. Verify the manufacturer’s quality control procedures are stringent before choosing one. This covers testing, routine inspections, and adherence to industry standards. Quality control procedures help to keep things consistent, cut down on errors, and make make sure the finished product lives up to your expectations.

Communication and collaboration promote success

A successful partnership with manufacturers requires effective communication and collaboration. To ensure that your vision is accurately translated into the final product and to prevent misunderstandings, provide regular updates, clear instructions, and constructive criticism. A manufacturer who is flexible and willing to work with you is a great resource.

Understand contracts and agreements

The legal aspects of a partnership with a jewelry manufacturer must be understood before signing. Examine contracts and agreements thoroughly, taking note of clauses pertaining to payment terms, intellectual property rights, production schedules, and dispute resolution. To make sure that your interests are properly safeguarded, it is advised that you consult with legal counsel.

Pros and Cons of Working with Overseas Manufacturers

Gaining access to special materials and processes as well as cost savings can be obtained by collaborating with foreign manufacturers. Long delivery times, cultural disparities, and language barriers are some of the difficulties it faces. Making an informed decision requires carefully weighing the benefits and drawbacks as well as taking into account variables like import laws, shipping expenses, and communication.

FAQs

What should I look for in a jewelry manufacturer?

Quality of workmanship, experience and reputation, specialization, production capabilities, pricing and cost-effectiveness, turnaround time, communication and service, technical capabilities, minimum order quantity (MOQ), customization and design support, after-sales support, contracts and terms

How to ensure the quality of manufactured jewelry?

Choose reputable manufacturers, check their product portfolio, quality control process, material quality, manufacturing technology, sample inspection, certification and compliance, site visits, third-party quality inspection

Feedback loops, contracts and agreements, after-sales support, staying informed about industry standards and building long-term relationships

Is it better to collaborate with local manufacturers or overseas manufacturers?

local manufacturer

Pros: Easier communication, faster turnaround, quality control, supports local economy, regulatory compliance

Disadvantages: Higher cost, limitations in technology, materials or manufacturing capabilities

Overseas manufacturers

Pros: Cost-effectiveness, variety and scale, access to unique materials

Cons: Longer delivery times, remote monitoring of production quality

A Consideration for Decision

Business nature: Take into account whether your business model prioritizes cost reduction or supports local production and sourcing.

Requirements for quality: Assess your ability to oversee quality control when working with foreign manufacturers.

Scale and adaptability: Determine if the manufacturer can manage the volume of your production while remaining adaptable.

Market preferences: Find out if the people in your target market are more price sensitive or if they appreciate locally produced goods.

Sustainability and ethics: Take into account how manufacturing practices and the environment interact, as these can be important considerations for many consumers and brands.